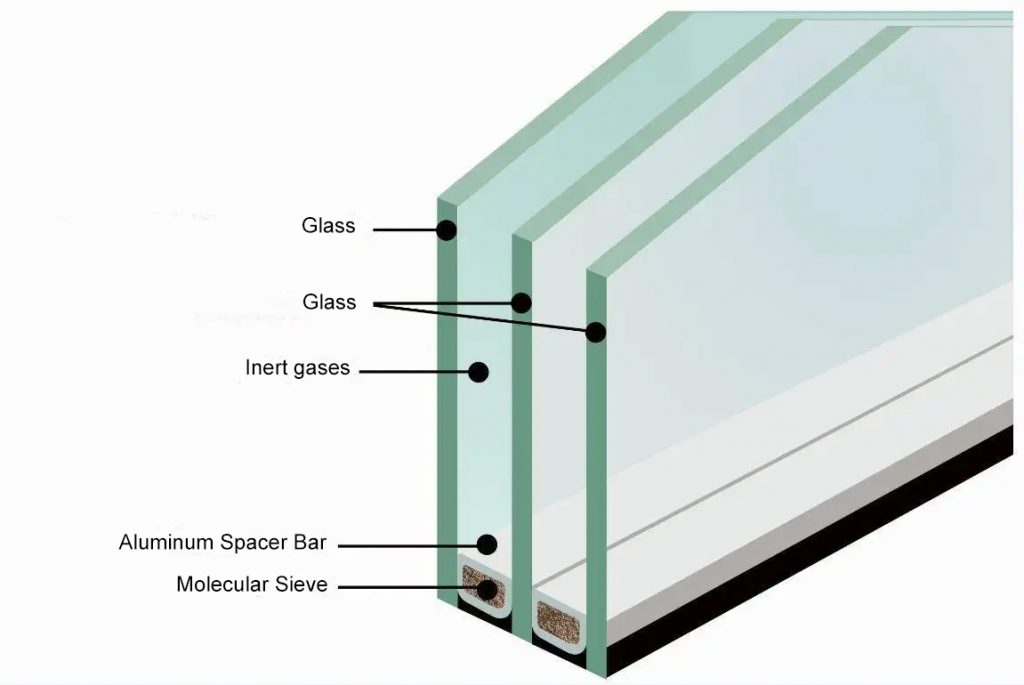

Insulating Glass Materials

Insulating glass is separated by two pieces of glass and an aluminum frame, with desiccant added in the middle. It has an excellent performance in heat insulation and sound insulation.

Besides glass, the production of insulating glass also requires aluminum spacer bars, sealants, and molecular sieves.

Aluminum Spacer Bar

The aluminum spacer bar is used to separate two or more pieces of glass.

Sealant

Sealant is used to secure the glass and aluminum spacer bar, and isolated it from air and water.

Molecular Sieve

Molecular sieves can absorb both water and residual organic matter in the insulating glass.

Aluminum Spacer Bar

It is made of 3003 alloy aluminum and adopts advanced roll-forming technology and a high-frequency welding process. The cutting surface is bright, non-oxidizing, non-corrosive, beautiful and generous, single-sided and double-empty, to ensure the activity of the desiccant. Aluminum thickness 0.3mm-0.5mm. The space bar width is 5.5mm-30.5mm, height 6.5mm, and length 5m.

Sealant

Butyl Sealant is the first sealing. The function is to realize the positioning assembly of the spacer frame-glass. It is effective to resist the penetration of water vapor. The second seal is silicone sealant, it fixes the whole structure and bonds the glass plate with the spacer bar so that the insulating glass can keep a good sealing effect under the load, and the overall structure is not affected.

Molecular Sieve

Molecular sieves made with zeolite and binder. It solves the problem of insulating glass desiccant dryer. The problem of distortion and breakage caused by the expansion or contraction of glass expands the service life of the insulating glass. Diameter 0.5mm-08mm (for machine filling)1.0mm-15mm(for machine labor)1.5mm-20mm(for labor filling).

Leave a Message

For product information, how to use it, or quotation, any questions please contact us.